Why More and More Factories Are Proactively Configuring Energy Storage Systems

In recent years, many factory owners have shared a common feeling: electricity is becoming more “expensive” and more “unstable”.

The Electricity Bill Is Becoming Harder to Calculate

Factories find their electricity bills increasing year by year despite stable consumption due to complex tariff structures such as peak and off-peak pricing, capacity charges, etc.

Power Cuts Are No Longer Occasional Incidents

Increased reliance on renewable energy sources has put pressure on grid management, making power cuts during high-demand periods more frequent. For factories, this means potential significant losses from halted production lines.

Factory Power Usage Is Getting More Complex

Modern factories now require higher quality power supply due to increased automation and digitalization, demanding solutions that can smooth load curves and mitigate peak loads.

Why Now?

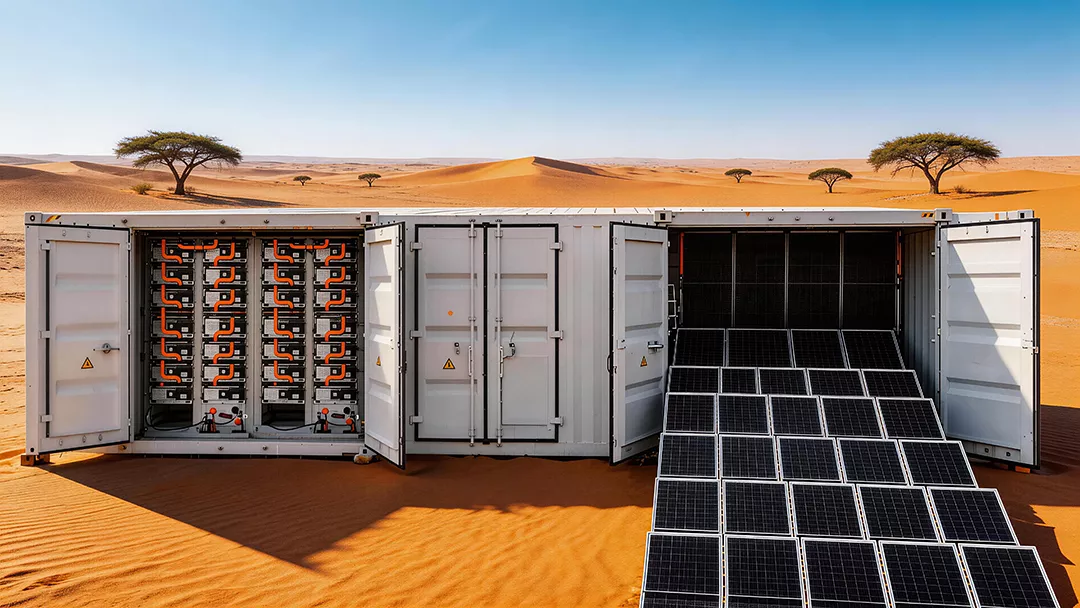

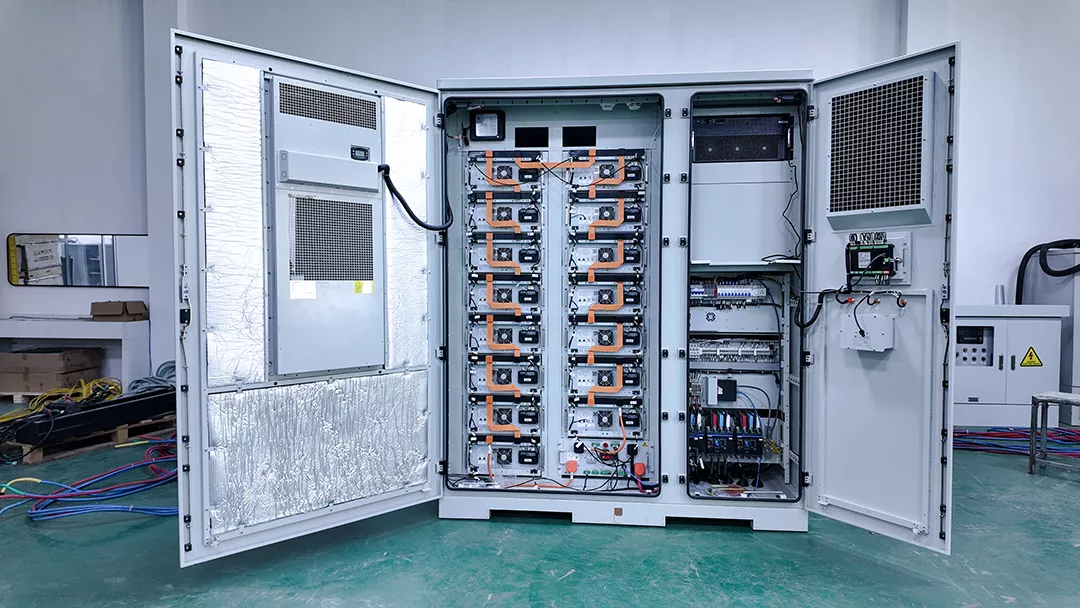

The timing for adopting energy storage systems is driven by reduced battery costs, more modular and standardized systems, smarter management systems, clearer policies, and tariff mechanisms, making it economically viable.

Energy Storage As an Operational Tool

Energy storage systems are transforming into operational tools that participate in decision-making processes concerning energy usage, contributing to lower costs and improved energy security.

For factories considering installing energy storage systems, the focus should be on finding solutions tailored to their specific needs rather than simply purchasing equipment. The true value of energy storage lies in its ability to effectively reduce electricity costs, provide stable power supply, and accommodate future expansion plans.

+86 13681781808

+86 13681781808