How do photovoltaic inverters withstand scorching temperatures exceeding 40°C?

This summer, numerous regions across China issued red alerts for extreme heat, with daytime temperatures in many cities approaching 40°C, creating conditions reminiscent of a ‘fiery furnace’. In such sweltering conditions, even humans struggle to leave air-conditioned spaces, while photovoltaic equipment operating outdoors faces immense challenges. Particularly concerning is the ‘core brain’ of photovoltaic systems – the inverter. How do these devices withstand the intense heat?

How damaging is high temperature to inverter components?

Photovoltaic inverters are complex devices integrating numerous high-precision electronic components, including core parts such as inductors, capacitors, and power semiconductor modules. High temperatures not only impair the operational efficiency of these components but also accelerate their ageing, shorten their lifespan, and may even trigger equipment failures.

Inductors: In high-temperature environments, inductors readily saturate, reducing their saturated inductance. This leads to increased current peaks, heightening the risk of overcurrent and potentially burning out power devices.

Capacitors: Aluminium electrolytic capacitors, in particular, are highly temperature-sensitive. Data indicates that for every 10°C increase in ambient temperature, their lifespan is halved. Although film capacitors demonstrate superior heat resistance, cost and size constraints limit their widespread adoption.

Power Modules: For power chips like IGBTs and MOSFETs, the ‘junction temperature’ serves as a critical performance threshold. Once the chip temperature exceeds its limit, ‘thermal breakdown’ occurs, directly causing inverter shutdown.

Thermal Design: The Inverter Manufacturer’s Secret Weapon

To ensure stable operation in high-temperature environments, photovoltaic inverters employ meticulously designed thermal management systems. The core principle is to maintain every component within its acceptable temperature range.

Common thermal management techniques include:

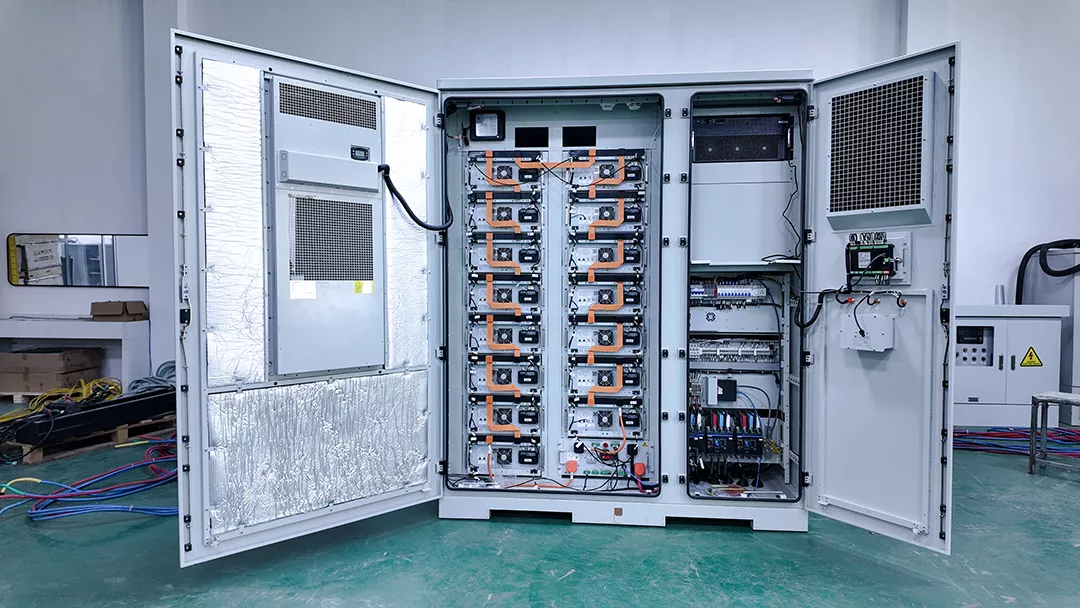

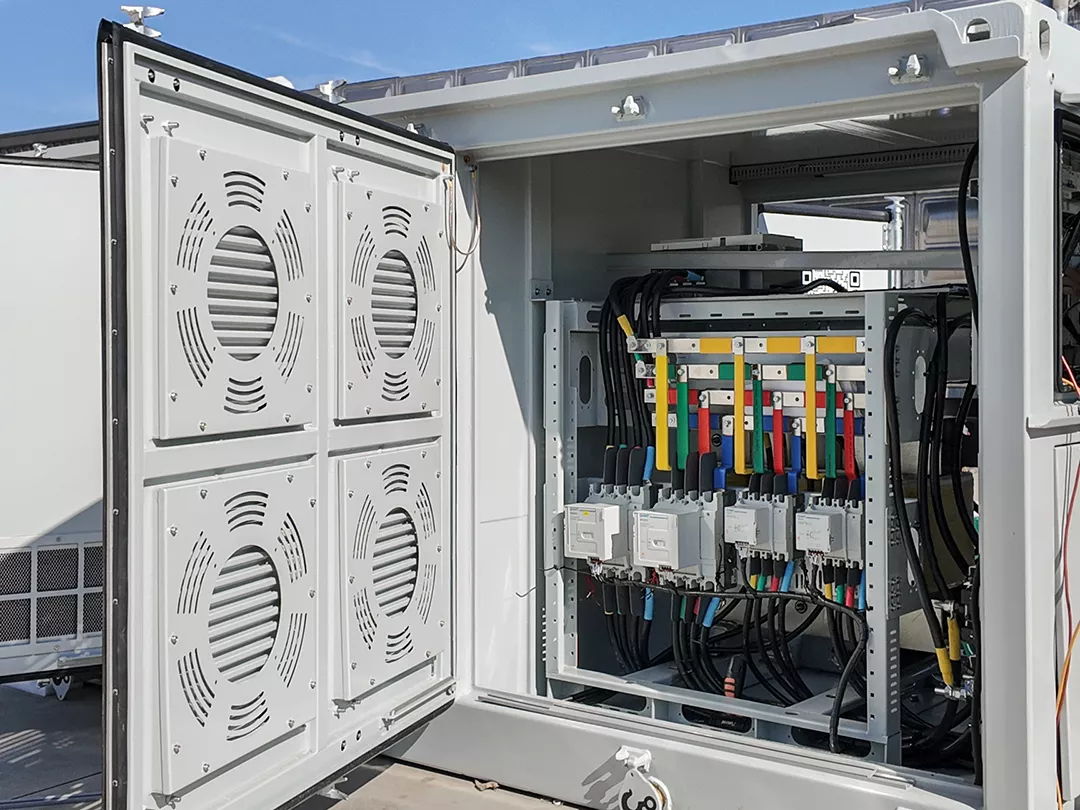

Air-cooling systems: Equipped with intelligent variable-speed fans that automatically adjust airflow based on internal temperature fluctuations, balancing dynamic cooling with energy efficiency and noise reduction.

Heat sink optimisation: Enhancing thermal exchange efficiency by increasing heat sink surface area, refining structures (e.g., serrated fin designs), and employing high-thermal-conductivity materials.

Integrated chassis design: Increasingly, premium inverters utilise aluminium alloy die-casting to fuse heat dissipation structures with the chassis. Combined with thermal silicone gel and heat spreaders, this facilitates rapid heat extraction.

For instance, certain brands’ ‘high-temperature tolerant’ inverters feature dual-insurance cooling systems comprising large-area rear fins and intelligent fans. This not only enhances adaptability in extreme environments but also ensures long-term system stability.

Inverter Heat Protection Strategies: Prioritising Installation and Maintenance

Beyond inherent high-temperature resistance, optimal installation environments and meticulous routine maintenance are equally vital.

Site Selection Matters: Install inverters in well-ventilated areas sheltered from direct sunlight. For outdoor installations, consider adding sunshades to reduce exposure to sunlight and rain. When mounting multiple inverters side-by-side, ensure sufficient spacing to facilitate effective heat dissipation.

Regular Cleaning is Essential: In high-temperature environments, dust easily accumulates on heat sinks and fans, compromising cooling efficiency. It is advisable to inspect the cooling system at least monthly for dust accumulation or foreign object blockages, undertaking prompt cleaning where necessary.

Monitor operational status: Regularly check the inverter display, LED indicators, and remote monitoring systems for alerts such as ‘over-temperature warnings’ or ‘fan malfunctions’. Should any anomalies arise, investigate immediately and contact professional after-sales support if required.

Final thoughts: High temperatures are not an act of God, but a litmus test for system design

As summer heatwaves intensify annually across China, an inverter’s thermal resilience has become a critical benchmark for product reliability. For PV plant owners and O&M personnel, selecting high-quality inverters with superior thermal management is fundamental to ensuring system profitability and stability.

High temperatures are not the enemy—unpreparedness is. Let us shield our PV inverters with a ‘heatwave shield’ to withstand summer’s scorching waves, ensuring every kilowatt-hour of green energy is delivered reliably.

+86 18721624519

+86 18721624519