Air humidity soars above 90%—how can photovoltaic inverters maintain stability in such damp conditions?

Recently, many southern cities have felt like they’re “submerged in water,” with air humidity persistently hovering above 90%—a rare occurrence for this time of year. Even northern cities like Beijing haven’t been spared, with humidity levels occasionally exceeding 90%. The combination of high temperatures and humidity creates a “natural sauna” effect, not only making people uncomfortable but also posing unprecedented challenges for outdoor equipment. This is especially true for photovoltaic inverters, which play a critical role in solar power generation systems. Facing such climatic challenges, they require sufficient “moisture resistance.”

What threats does high humidity pose to inverters?

As the core device converting DC power from solar panels into AC power, the inverter’s operational status directly impacts the stability and efficiency of the entire power generation system. However, prolonged exposure to extremely high humidity severely compromises its “health.”

First, high humidity easily causes water droplets to condense on the surfaces of internal circuit boards or components. These tiny droplets can lead to short circuits. If current flow is disrupted, the equipment may shut down and trigger alarms at best, or burn out critical electronic components at worst, resulting in significant economic losses.

Second, moisture weakens the inverter’s insulation capabilities. Many inverters utilize insulating materials internally, but when these materials absorb water, their resistance values decrease, intensifying leakage currents. This not only reduces operational efficiency but also creates safety hazards, increasing the risk of electric shock.

Additionally, high humidity accelerates oxidation and corrosion of the device’s metal components. Over time, this can lead to structural loosening and unstable electrical connections, further increasing the likelihood of failures.

How do inverter manufacturers combat moisture?

To address these challenges, leading inverter manufacturers have implemented robust design and production strategies.

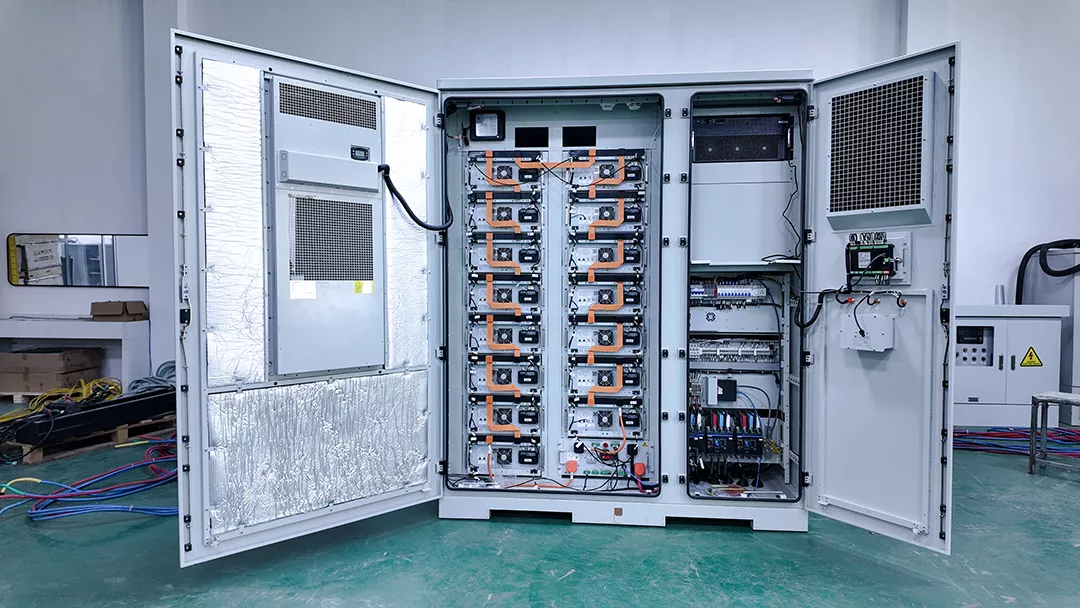

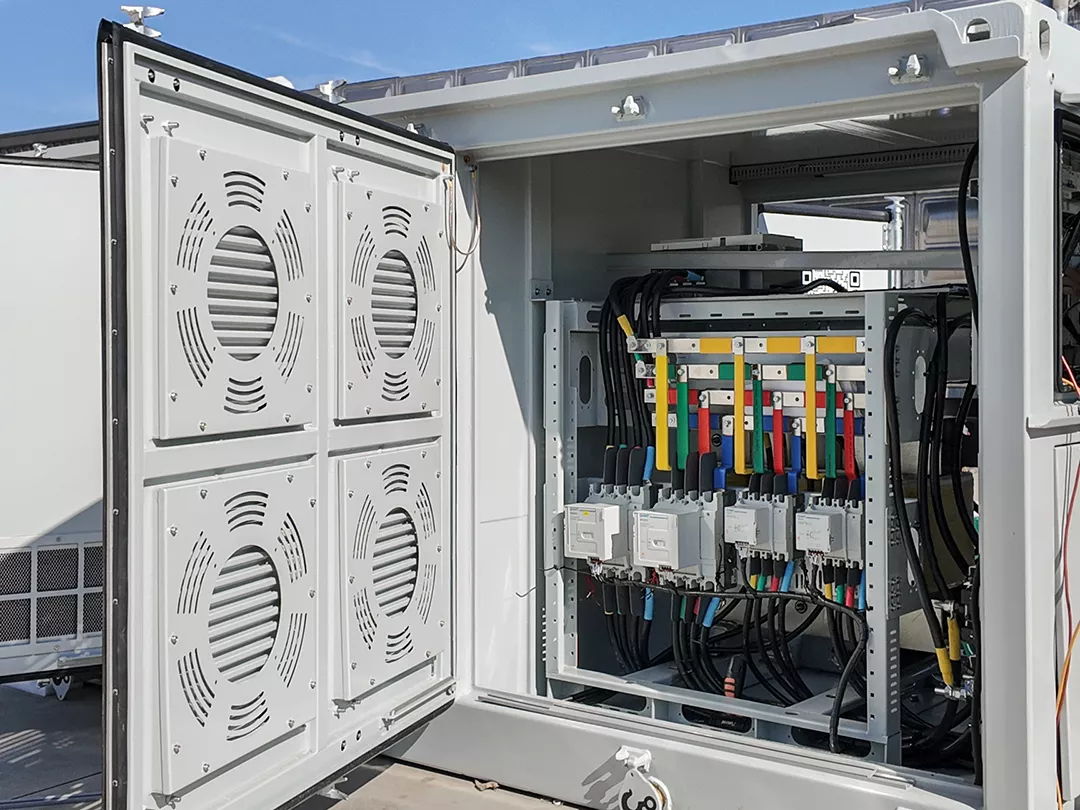

First, they enhance the overall protection rating. Many outdoor inverters feature IP65 or higher waterproof and dustproof designs, where “6” signifies complete dust ingress prevention and “5” indicates resistance to water jets from any direction. This structure effectively blocks moisture from entering the inverter’s interior, establishing the first line of defense for components.

Second, manufacturers apply moisture-resistant protective coatings to internal circuit boards. Like an invisible raincoat for electronic components, this coating prevents moisture adhesion and accumulation, reducing risks of short circuits and corrosion.

Some high-end models also feature intelligent humidity monitoring systems. When internal humidity exceeds preset thresholds, the system automatically activates heating or dehumidification functions to proactively regulate the internal environment, ensuring the equipment consistently operates within stable, safe humidity ranges.

Operational Management: The Second Front in Inverter Moisture Protection

Beyond the product’s inherent “hardware capabilities,” meticulous management during post-installation operations is equally critical. Regularly inspecting seals and joint gaskets for aging or damage is essential for maintaining integrity. Even an inconspicuous small crack can become a “breach point” for moisture.

In seasons or regions with exceptionally high humidity, optimizing the inverter’s installation environment is also necessary. For instance, placing industrial desiccants inside equipment rooms or enclosures, or deploying dehumidifiers to reduce overall humidity levels. Ventilation can also be enhanced by optimizing installation locations to avoid “stuffy” conditions, accelerating moisture circulation and expulsion.

Where feasible, installing inverters away from low-lying, damp areas or adding auxiliary equipment like rain shelters and ventilation louvers can effectively reduce humidity’s corrosive impact on equipment.

Conclusion

In high-humidity environments, photovoltaic inverters face not only moisture but also multiple challenges to operational reliability and lifespan. Only through enhanced protection in design, meticulous attention to detail in manufacturing, and rigorous monitoring during operation and maintenance can true “all-weather operation” be achieved—ensuring efficient, stable, and long-lasting performance even in humid climates.

As solar power enters millions of households, safeguarding the inverter—the heart of the system—is a critical step toward achieving sustainable green energy. When confronting moisture assaults, a scientific moisture-proof strategy builds a robust safety barrier for the entire photovoltaic system.

+86 18721624519

+86 18721624519